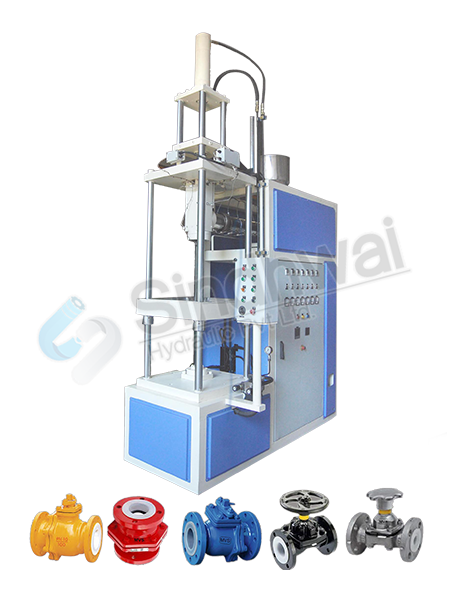

Transfer Molding Machine Manufacturer

A Transfer Molding Machine (TMM) is a specialized piece of equipment used in the manufacturing process of plastic and rubber components, primarily in industries such as automotive, electronics, medical, and consumer goods. This machine uses a combination of heat and pressure to mold materials, offering precision and efficiency in producing complex parts. Transfer molding is a variation of compression molding that allows for more intricate designs and the use of various materials, including thermosetting plastics, elastomers, and other polymers.

The process begins by placing a pre-measured amount of material, typically in the form of a pellet or preform, into a heated transfer chamber. The material is then transferred via a plunger into a mold cavity under high pressure, where it is shaped according to the mold's design. The mold cavity is typically made of steel or aluminum and is designed to produce parts with detailed and precise features. As the material cures within the mold under controlled heat and pressure, it solidifies and takes the desired shape.

The versatility of Transfer Molding Machines also allows for high-volume production with minimal waste, as the process ensures consistent part quality and reduces material scrap. Transfer molding is also preferred for producing parts with tight tolerances, as the machine's precision controls ensure accurate and repeatable results. However, the initial setup for a transfer molding process can be time-consuming and requires significant expertise to optimize the mold design, material flow, and curing parameters.

Transfer Molding Machine Features :

Precise Control Over Temperature and Pressure: Transfer molding machines offer accurate temperature and pressure control, ensuring consistent and repeatable results in the molding process. This is essential for producing high-quality parts with precise dimensions.

- Versatility in Material Handling: Transfer molding can handle a variety of materials, including thermosetting plastics, elastomers, and composites. It also allows for the inclusion of inserts or metal components, which adds to its versatility.

- Complex Part Design Capability: The process is ideal for creating intricate and detailed part designs with complex geometries. This makes it suitable for industries requiring components with fine features or precise shapes.

- Mold Design Flexibility: The machine can accommodate multiple cavity molds and multi-stage molds, providing flexibility in part production and improving overall manufacturing efficiency.

- Consistency and Repeatability :Once set up, transfer molding machines deliver consistent and repeatable results, which is crucial for industries with strict quality standards and tight tolerances.

- Incorporation of Inserts : Unlike other molding processes, transfer molding allows for the integration of metal or other material inserts into the molded part. This feature is valuable for producing composite parts with enhanced properties such as strength, conductivity, or heat resistance.

Benefits of Transfer Molding Machine:

- High Precision: Transfer molding offers exceptional accuracy, especially for intricate and complex parts. This is important for industries where precision is critical, such as electronics and medical devices.

- Material Efficiency: The process minimizes material waste by precisely measuring and injecting the material into the mold. This results in cost savings and contributes to more sustainable manufacturing practices.

- Enhanced Mechanical Properties: Transfer molding can be used with thermosetting plastics and elastomers, which cure to form durable and strong parts. These materials often provide excellent heat resistance, electrical insulation, and mechanical strength.

- Improved Production Efficiency:The automation of the transfer molding process reduces manual labor, streamlines production, and allows for faster cycle times. This makes it ideal for high-volume manufacturing.

- Cost-Effective for Complex Parts: the initial mold setup may be costly, the ability to produce highly detailed and multi-material parts with minimal waste makes transfer molding cost-effective in the long run.

Applications of Transfer Molding

- Automotive Industry:Transfer molding is commonly used to produce components such as gaskets, seals, electrical connectors, and bushings. These parts require durability, precision, and the ability to withstand harsh environments.

- Electronics: The process minimizes material waste by precisely measuring and injecting the material into the mold. This results in cost savings and contributes to more sustainable manufacturing practices.

- Medical Devices: In the medical field, transfer molding is used to produce components like seals, gaskets, and housings for devices that require tight tolerances, biocompatibility, and reliability

- Consumer Goods: such as electrical appliance components, buttons, and other molded plastic parts can be efficiently manufactured using transfer molding.

- Aerospace and Defense: Transfer molding is used to create complex parts that need to meet high-performance standards, such as seals, connectors, and other critical components that require both durability and precision.